Henan LIMING Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipments was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together

MOBILE CRUSHERS

Stationary Crushers

Grinding Mills

Accessory Equipment

OUR

Applications

LATEST

NEWS

Limestone powder brings benefit to concrete mixing plant

Recycled Material Crushers: Eco-Friendly Concrete & Asphalt Shredders 21/2/2025

In an era of sustainable construction and circular economies, recycled material crushers are revolutionizing how industries manage concrete, asphalt, and demolition waste. These specialized machines transform discarded materials into reusable aggregates, reducing landfill waste and conserving natural resources.

Environmental Impact:

Reduce carbon emissions by repurposing concrete and asphalt waste instead of mining virgin materials.

Cost Efficiency:

Lower disposal costs and generate revenue by selling recycled aggregates for new projects.

Regulatory Compliance:

Meet strict environmental regulations (e.g., EPA standards) for waste management and emissions.

Versatility:

Process mixed debris, including rebar-embedded concrete and aged asphalt, with precision.

High-Capacity Crushing:

Process up to 500 tons/hour of concrete or asphalt with advanced jaw or impact crushers.

Magnetic Separation:

Automatically extract rebar and metal contaminants for cleaner output.

Dust Suppression Systems:

Integrated water sprays or vacuum filters minimize airborne particles.

Portability:

Mobile units enable on-site recycling, reducing transport costs and emissions.

Road Construction:

Crushed concrete replaces gravel in sub-base layers.

Building Foundations:

Recycled aggregates provide stable fill material.

Landscaping:

Repurposed asphalt serves as durable pathways or drainage solutions.

Material Type:

Opt for impact crushers for softer asphalt or jaw crushers for dense concrete.

Output Size:

Adjustable settings ensure aggregates meet project specifications (e.g., 20mm-50mm).

Mobility Needs:

Track-mounted crushers offer flexibility for urban demolition sites.

Recycled material crushers are no longer optional—they’re essential for eco-conscious businesses. By investing in these shredders, companies reduce waste, cut costs, and align with global sustainability goals like the UN’s SDGs.

Upgrade Your Operations Today

Explore our range of eco-friendly concrete and asphalt crushers to start converting waste into value. Request a quote or schedule a demo to see how our technology can elevate your recycling efficiency.

Crusher Spare Parts Catalog- Jaws and Liners 12/2/2025

In the world of crushing equipment, maintaining optimal performance is critical. Whether you're operating a jaw crusher, cone crusher, or impact crusher, the jaws and liners are among the most essential components that ensure efficient material processing. Over time, these parts wear down due to constant friction and pressure, leading to reduced productivity and increased downtime. That’s why having a reliable Crusher Spare Parts Catalog for jaws and liners is crucial for every operation.

In this guide, we’ll explore everything you need to know about crusher jaws and liners, including their importance, types, materials, and how to choose the right spare parts for your equipment. Let’s dive in!

Crusher jaws and liners are the workhorses of any crushing system. They directly interact with raw materials, breaking them down into smaller, manageable sizes. Here’s why they’re indispensable:

Efficiency: High-quality jaws and liners ensure consistent crushing performance, reducing energy consumption and operational costs.

Durability: Made from wear-resistant materials, they withstand extreme conditions, extending the lifespan of your crusher.

Cost Savings: Regularly replacing worn-out jaws and liners prevents costly damage to other crusher components.

Product Quality: Properly functioning jaws and liners produce uniformly sized material, essential for downstream processes.

Crusher jaws and liners come in various designs and materials, tailored to specific applications and equipment types. Here’s a breakdown:

Fixed Jaws: Stationary plates that provide a surface for material to be crushed against.

Moving Jaws: Oscillating plates that apply pressure to break down materials.

Cheek Plates: Side liners that protect the crusher frame from wear.

Mantle Liners: The upper wear surface that gyrates to crush material.

Concave Liners: The stationary lower surface that works with the mantle to achieve crushing.

Blow Bars: Striking components that impact and break down materials.

Side Liners: Protective plates that shield the crusher’s interior from wear.

The material composition of jaws and liners plays a significant role in their performance and longevity. Common materials include:

Manganese Steel: Known for its exceptional toughness and wear resistance, ideal for high-impact applications.

High Chrome Iron: Offers superior abrasion resistance, perfect for crushing abrasive materials like granite or basalt.

Martensitic Steel: Combines hardness and durability, suitable for medium-impact crushing.

Composite Materials: Advanced blends that provide a balance of strength and cost-effectiveness.

Selecting the correct jaws and liners for your crusher is crucial for maximizing efficiency and minimizing downtime. Here’s what to consider:

Crusher Model: Ensure the spare parts are compatible with your specific crusher brand and model (e.g., Metso, Sandvik, Terex).

Material Type: Choose materials based on the hardness and abrasiveness of the materials you’re crushing.

Operating Conditions: Consider factors like feed size, production capacity, and environmental conditions.

OEM vs. Aftermarket: OEM parts guarantee compatibility, while aftermarket options often provide cost savings without compromising quality.

Supplier Reputation: Work with a trusted supplier that offers certified, high-quality spare parts and reliable customer support.

If you’re looking for a trusted source for crusher spare parts, look no further. Our Crusher Spare Parts Catalog features a wide range of high-quality jaws, liners, and wear parts for all major crusher brands. Whether you need OEM or aftermarket solutions, we’ve got you covered.

Why Choose Us?

Extensive inventory of crusher spare parts

Competitive pricing and fast shipping

Expert technical support and guidance

Custom solutions tailored to your needs

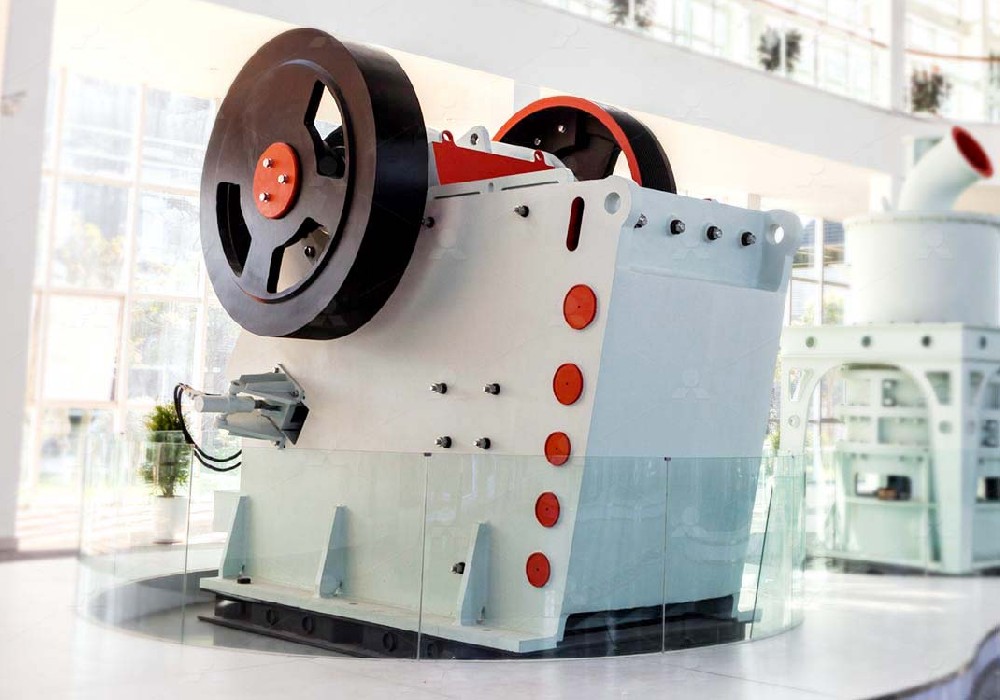

The Ultimate Guide to Jaw Crushers: Reliable Crushing Solutions for Your Projects 7/2/2025

Introduction

Jaw crushers are one of the most widely used crushing machines in the mining, quarrying, and construction industries. Known for their robust design, high efficiency, and versatility, jaw crushers are ideal for primary crushing of hard and abrasive materials. Whether you’re processing granite, basalt, limestone, or other materials, jaw crushers deliver consistent performance and reliability.

In this article, we’ll explore the key features, working principles, and benefits of jaw crushers, as well as how to choose the right one for your project.

What is a Jaw Crusher?

A jaw crusher is a heavy-duty machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It consists of two vertical jaws—one fixed and one movable—that create a V-shaped cavity. The material is fed into the top of the crusher and is crushed as the movable jaw exerts force against the fixed jaw.

Key Features of Jaw Crushers

High Crushing Efficiency: Jaw crushers are designed to handle large feed sizes and produce uniform output, making them ideal for primary crushing.

Durable Construction: Built with high-quality materials, jaw crushers are resistant to wear and tear, ensuring long service life even in tough conditions.

Versatility: Suitable for a wide range of materials, including hard and abrasive rocks, ores, and recycled concrete.

Easy Maintenance: Simple design and accessible components make jaw crushers easy to maintain and repair.

Adjustable Discharge Size: The output size can be adjusted to meet specific project requirements, providing flexibility for different applications.

How Does a Jaw Crusher Work?

The working principle of a jaw crusher is straightforward:

Material is fed into the crushing chamber from the top.

The movable jaw compresses the material against the fixed jaw, breaking it into smaller pieces.

The crushed material exits through the bottom discharge opening, with the size determined by the gap between the jaws.

Applications of Jaw Crushers

Jaw crushers are used in various industries, including:

Mining: Crushing ores and minerals for further processing.

Quarrying: Producing aggregates for construction projects.

Recycling: Processing concrete and demolition waste for reuse.

Construction: Crushing rocks and stones for road building and infrastructure projects.

Why Choose Liming Jaw Crushers?

At Liming, we specialize in manufacturing high-performance jaw crushers under the Liming brand. Our jaw crushers are designed to meet the highest industry standards, offering:

Advanced Technology: Innovative designs for improved efficiency and productivity.

Custom Solutions: Tailored configurations to match your specific project requirements.

Global Support: Comprehensive after-sales service and technical support to ensure your equipment operates at peak performance.

How to Choose the Right Jaw Crusher

When selecting a jaw crusher, consider the following factors:

Material Type: Choose a crusher that can handle the hardness and abrasiveness of your material.

Production Capacity: Ensure the crusher can meet your required output (tons per hour).

Feed Size: Select a crusher that can accommodate the size of your raw material.

Discharge Size: Determine the desired output size for your project.

Power Consumption: Opt for energy-efficient models to reduce operational costs.

Conclusion

Jaw crushers are an essential piece of equipment for any project involving material crushing. With their robust design, high efficiency, and versatility, they provide reliable solutions for a wide range of applications.

At Liming, we are committed to delivering top-quality jaw crushers and exceptional customer service. If you’re looking for a reliable crushing solution, contact us today to learn more about our products and how we can support your project.

![]() Ready to find the perfect jaw crusher for your needs? Visit our website or contact our team for expert advice and customized solutions.

Ready to find the perfect jaw crusher for your needs? Visit our website or contact our team for expert advice and customized solutions.

Why

Choose Us

Passionate

Professional

Support