GROUP NEWS

The Ultimate Guide to Jaw Crushers: Reliable Crushing Solutions for Your Projects

Introduction

Jaw crushers are one of the most widely used crushing machines in the mining, quarrying, and construction industries. Known for their robust design, high efficiency, and versatility, jaw crushers are ideal for primary crushing of hard and abrasive materials. Whether you’re processing granite, basalt, limestone, or other materials, jaw crushers deliver consistent performance and reliability.

In this article, we’ll explore the key features, working principles, and benefits of jaw crushers, as well as how to choose the right one for your project.

What is a Jaw Crusher?

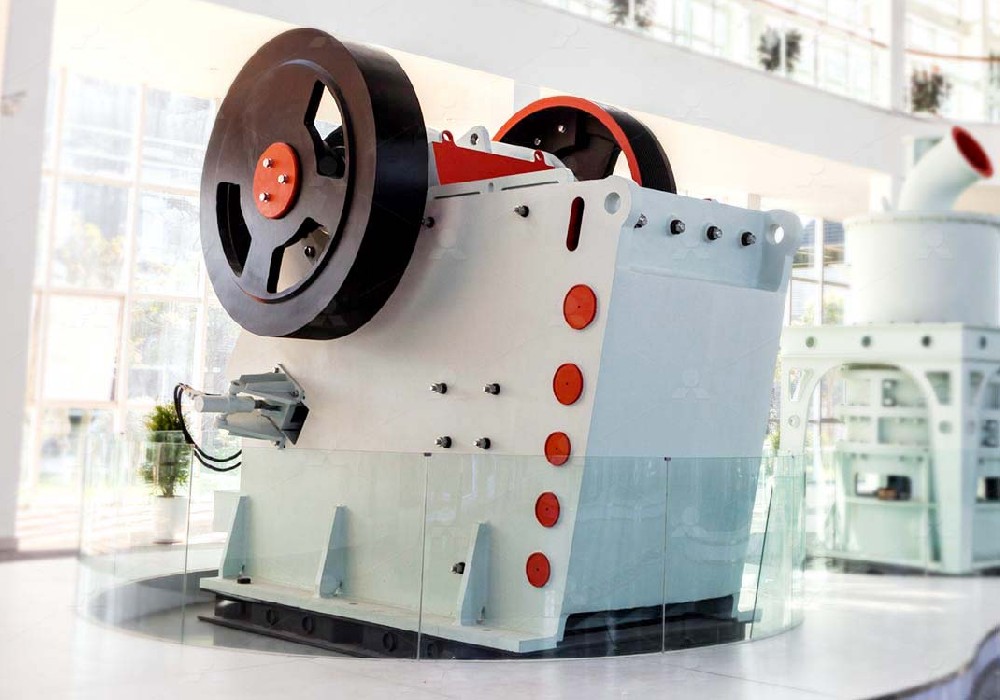

A jaw crusher is a heavy-duty machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It consists of two vertical jaws—one fixed and one movable—that create a V-shaped cavity. The material is fed into the top of the crusher and is crushed as the movable jaw exerts force against the fixed jaw.

Key Features of Jaw Crushers

High Crushing Efficiency: Jaw crushers are designed to handle large feed sizes and produce uniform output, making them ideal for primary crushing.

Durable Construction: Built with high-quality materials, jaw crushers are resistant to wear and tear, ensuring long service life even in tough conditions.

Versatility: Suitable for a wide range of materials, including hard and abrasive rocks, ores, and recycled concrete.

Easy Maintenance: Simple design and accessible components make jaw crushers easy to maintain and repair.

Adjustable Discharge Size: The output size can be adjusted to meet specific project requirements, providing flexibility for different applications.

How Does a Jaw Crusher Work?

The working principle of a jaw crusher is straightforward:

Material is fed into the crushing chamber from the top.

The movable jaw compresses the material against the fixed jaw, breaking it into smaller pieces.

The crushed material exits through the bottom discharge opening, with the size determined by the gap between the jaws.

Applications of Jaw Crushers

Jaw crushers are used in various industries, including:

Mining: Crushing ores and minerals for further processing.

Quarrying: Producing aggregates for construction projects.

Recycling: Processing concrete and demolition waste for reuse.

Construction: Crushing rocks and stones for road building and infrastructure projects.

Why Choose Liming Jaw Crushers?

At Liming, we specialize in manufacturing high-performance jaw crushers under the Liming brand. Our jaw crushers are designed to meet the highest industry standards, offering:

Advanced Technology: Innovative designs for improved efficiency and productivity.

Custom Solutions: Tailored configurations to match your specific project requirements.

Global Support: Comprehensive after-sales service and technical support to ensure your equipment operates at peak performance.

How to Choose the Right Jaw Crusher

When selecting a jaw crusher, consider the following factors:

Material Type: Choose a crusher that can handle the hardness and abrasiveness of your material.

Production Capacity: Ensure the crusher can meet your required output (tons per hour).

Feed Size: Select a crusher that can accommodate the size of your raw material.

Discharge Size: Determine the desired output size for your project.

Power Consumption: Opt for energy-efficient models to reduce operational costs.

Conclusion

Jaw crushers are an essential piece of equipment for any project involving material crushing. With their robust design, high efficiency, and versatility, they provide reliable solutions for a wide range of applications.

At Liming, we are committed to delivering top-quality jaw crushers and exceptional customer service. If you’re looking for a reliable crushing solution, contact us today to learn more about our products and how we can support your project.

![]() Ready to find the perfect jaw crusher for your needs? Visit our website or contact our team for expert advice and customized solutions.

Ready to find the perfect jaw crusher for your needs? Visit our website or contact our team for expert advice and customized solutions.

CONTACT US

Related News...

Liming Heavy Industry Presents State-of-the-Art Crushing Solutions at the 137th Canton Fair

7/4/2025

Industrial Material Processing Reinvented by High Crushing Ratio Crushers

2/4/2025

Crushers with High Crushing Ratio - Maximize Your Output

27/3/2025

Jaw Crusher 101: How It Works, Applications, and Benefits

20/3/2025

Successful Case of Zambia Iron Ore Processing Project

3/13/2025

Recycled Material Crushers: Eco-Friendly Concrete & Asphalt Shredders

21/2/2025

Crusher Spare Parts Catalog- Jaws and Liners

12/2/2025

The Ultimate Guide to Jaw Crushers: Reliable Crushing Solutions for Your Projects

7/2/2025